From Blueprint to Streetscape: The Birth of the Aluminum Facade of FALCONERI Store in Tokyo

0

0

0

When you pass by the corner of Tokyo's Omotesando, it’s hard not to be captivated by the building's facade—vertical aluminum elements with a deep brown metallic finish, set against a glass curtain wall, appear both modern and warm. This is far more than just a metal panel; it is an “urban sculpture,” meticulously refined at every stage from structural design, surface treatment, and packaging transportation to on-site installation.

1. Initial Design: Defining the Skeleton of Space with Aluminum

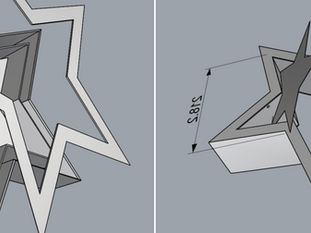

During the structural design phase, we repeatedly simulated with BIM software: the spacing of each aluminum element, load-bearing nodes, and the connection methods to the glass curtain wall were all rigorously calculated to ensure safety and aesthetics could coexist in Japan, a region prone to typhoons and earthquakes.

At the project’s outset, our core objective was to create a facade that felt both lightweight and powerful, one that echoed the brand’s Italian minimalist style while standing out within Tokyo's urban fabric. After multiple rounds of material comparisons, we ultimately chose aluminum alloy as the primary material:

• Lightweight Advantage: With a density only one-third that of steel, aluminum significantly reduces the building load, allowing the vertical elements to be designed more slenderly to achieve a "visually floating" effect.

• Structural Malleability: Through extrusion molding, we were able to create custom cross-sections with grooves and edges, giving the facade a rich sense of depth.

• Weather Resistance: Tokyo’s climate is rainy and humid. Aluminum’s natural corrosion resistance ensures the facade maintains its original texture for years to come.

2. Surface Treatment: The Warmth and Precision of Painting

This distinctive deep brown hue is the highlight of the entire project. Through repeated sampling and communication, we finalized the paint formulation featuring a matte metallic sheen:

• Pre-treatment Process: All aluminum components underwent rigorous degreasing, phosphating, and passivation before painting, ensuring strong adhesion between the coating and the metal substrate to prevent peeling or flaking in the future.

• Spraying Technology: Electrostatic powder coating was employed to ensure uniform adhesion of the paint to the aluminum surface, followed by high-temperature curing to form a dense, wear-resistant protective film. This process is not only environmentally friendly but also resists UV rays and acid rain erosion.

• Color Control: Painting for each batch of components was completed in a controlled environment with constant temperature and humidity. We strictly monitored color consistency using a colorimeter to ensure every piece of aluminum, from factory to site, matched perfectly, ultimately achieving a seamless visual effect.

3. Packaging and Transportation: Precision Protection for Every Inch of the CoatedSurface

Before arriving at the construction site, the coated aluminum components undergo a crucial "armor" process—professional packaging, which is key to ensuring the painted surface remains flawless:

• Individual Protection: Each aluminum element is first wrapped 360° with foam and bubble wrap to prevent scratches or impacts during transportation.

• Compartmentalized Securing: Within custom wooden crates or pallets, components are secured using custom foam slots and straps to prevent movement and collisions during transit, while avoiding contact between the painted surfaces of different components.

• Full Traceability: Each batch of packaging has a dedicated logistics label. We monitor the shipping status from the factory to the site, ensuring every piece of aluminum arrives at the destination "unharmed."

4. On-site Installation: Precise Collaboration Behind the Scaffolding

When you see the building covered in scaffolding in photographs, it’s hard to imagine that the installation of each aluminum element is as precise as “building blocks”:

• Prefabricated Production: All aluminum components are prefabricated in the factory, including cutting, drilling, and painting, minimizing on-site construction errors and pollution.

• Modular Installation: The facade is divided into several standard modules. After pre-assembly in the factory, they are transported to the site for hoisting and installation. The position of each element is calibrated using laser positioning equipment to ensure the vertical lines are perfectly straight.

• Detailing and Sealing: The most challenging part was the connection between the aluminum elements, the glass curtain wall, and the building corners. We customized specialized metal trim and sealant, ensuring both waterproof performance and clean, seamless transitions without any extraneous lines disrupting the overall aesthetic.

5. Final Presentation: When Metal Breathes with the City’s Light and Wind

Today, the scaffolding has been dismantled, and the building has officially become part of Tokyo’s streetscape. Sunlight falls on the deep brown aluminum surface, with shadows in the grooves shifting with the passage of time; on rainy days, water droplets bead on the matte finish, slowly sliding down along the edges.

This is exactly what we wanted: a warm metallic facade. It is not a cold building skin but rather a “skin” that engages in dialogue with the city. From the lines on the blueprint to the scenery on the street, each step is imbued with reverence for craftsmanship—this is the charm of an aluminum facade and our commitment to "good design."

At Caamatech, we have always believed that good display fixtures are never just about “display”; they are an extension of brand spirit. Whether it’s the facade of a commercial space or a display shelf within a counter, our dedication to materials, craftsmanship, and details remains unwavering. We insist on using the lightness and resilience of aluminum to create visual carriers for every brand that stand the test of time. We insist on pushing structural safety, surface texture, and user experience to the limit in every project. Because we deeply understand that true professionalism lies in the unseen details and in every repeated pursuit of “better.”