Walk through the brightly lit beauty section of a department store, and you’ll likely be drawn to the perfume bottles gleaming under spotlights, the perfectly arranged rainbows of lipstick, and the elegantly displayed foundations. But many of these eye-catching items aren’t filled with actual product—they are what the industry calls Display Factices: meticulously designed and manufactured professional display models. Far from being mere substitutes, these models are an essential visual language in modern retail, serving as a sensory bridge between brand and consumer when direct product interaction isn’t possible.

The Strategic Role in Retail Psychology

In the luxury and beauty industries, first impressions often determine sales success. However, due to hygiene considerations, preservation requirements, and cost control, genuine high-end products are rarely available for direct testing. Display Factices emerged to address this gap, tasked with conveying the core product experience. They must not only look authentic but also communicate quality through material, weight, gloss, and other subtle details—creating a sensory illusion that builds brand trust. When a customer touches a matte-finish lipstick model or gazes at the “liquid” inside an acrylic bottle, desire is silently ignited.

Precision Manufacturing Deconstructed: From Concept to Counter

Foundation and Forming Technologies

3D Printing

The journey begins with digital precision. Using industrial 3D scanning, we capture every contour, thread, and texture of a real product with an accuracy of up to 0.2 mm. When CAD files are provided, this digital collaboration ensures a seamless translation of brand DNA from concept to physical form.

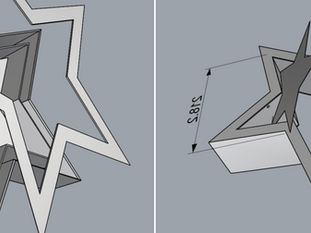

We then employ high-precision 3D printing—specifically SLA (stereolithography) and DLP (digital light processing)—to create detailed prototypes. SLA builds smooth, dimensionally accurate parts layer by layer, ideal for complex geometries. DLP offers faster printing while maintaining fine vertical resolution. These prototypes are not just visual aids but functional tools for testing assembly, material thickness, and light interaction.

Injection Molding and Thermoforming

For mass production, injection molding and thermoforming take center stage. Using all-electric injection machines and molds with a tight tolerances , we produce consistent components—from acrylic bottles to PETG caps—with micrometer-level precision.

For lightweight, hollow structures, we use high-pressure thermoforming with medical-grade PS or PET sheets. Heated and formed over custom molds under controlled pressure, these parts are then finished with CNC trimming to achieve smooth, seamless edges.

Fiberglass Reinforced Plastic (FRP) for Large-Scale Art

When displays become large-scale installations—perfume towers or brand sculptures—FRP offers unparalleled sculptural potential. Using aerospace-grade fiberglass and vinyl ester resin, we hand-layer fiber mats in calculated orientations, then apply vacuum bagging to remove air bubbles and ensure a dense, smooth finish. The result is a strong, lightweight structure capable of bringing bold brand visions to life.

Advanced Material Science

Acrylic Innovations

We use only top-tier cast acrylic sheets, prized for their crystal-clear transparency and UV resistance. Special additives act as an “optical sunscreen,” protecting colors and clarity from fading under intense retail lighting—ensuring displays remain vibrant for years.

Metal Craftsmanship

Metal components communicate quality through touch and sight. We stainless steel parts using five-axis CNC centers, then polish them to a flawless 8K mirror finish. For color and durability, we apply PVD (physical vapor deposition) coatings—creating shades like rose gold or black chrome that withstand wear while maintaining their luster.

Surface Treatment: A Sensory Revolution

Surface finishing is where visual and tactile illusions are perfected. We use UV digital printing at 1200 dpi for photorealistic, durable graphics. For texture, techniques like glass bead blasting create velvety matte finishes, while chemical etching replicates fine details like leather grain or silk weave. Every treatment is designed to engage multiple senses and reinforce brand perception.

Caamatech: A Global Partner in Luxury Display Solutions

With cross-cultural expertise and a vertically integrated smart factory in Suzhou, Caamatech transforms brand essence into tangible experiences. We collaborate with leading chemical firms to develop custom materials that resist fading and wear. Looking ahead, we’re pioneering interactive factices—embedding micro-sensors and dynamic surfaces to turn passive displays into engaging touchpoints between physical and digital brand worlds.

Every time a customer picks up a display model, a silent brand conversation begins. At Caamatech, we craft not just models, but trust—through details unseen and sensations subtly felt. Because true luxury never shouts; it speaks in the quiet perfection of detail.